-

FIBC Bag Specification

ITEMSPECIFICATION

Material PolyPropylene Inner Liner PolyEthylene Construction 13 x 13 Denier / Weight (1m x 1m) ≥ 180-200 Heavy Duty

≥ 80-100 Light DutyWeft 1750D Warp 1750D Dimension 915mm ~ 1150mm Length 1020mm ~ 2035mm Printing Yes (Available) Max 3 colour Type of accessories Top and Bottom Spouts, Top Duffle, Bottom Close Strap / Lifting Belt 80mm ~ 100mm (PP) Safety Factor 1:5:1, 1:6 Load 100kg ~ 2000kg Application of Products PP Resin, Slush, Sand, Powder, Solid, Fertilizer & etc. -

Fabric Specification

LIGHT DUTY LAMINATED

SizeLaminated / Non

LaminatedMinimum Orders

(Meter)Fabric 46”  2000 meter

2000 meterFabric 48”  2000 meter

2000 meterFabric 58”  2000 meter

2000 meterHEAVY DUTY (15 x 15) 1500D

SizeNon

LaminatedNon Laminate &

Reinforce 8 bandsMinimum Orders

(meter)Fabric 44” flat

1500 meter

1500 meterFabric 46” flat

1500 meter

1500 meterFabric 68” circular

1500 meter

1500 meterFabric 72” circular

1500 meter

1500 meterFabric 74” circular

1500 meter

1500 meterFabric 80” circular

1500 meter

1500 meterLIGHT DUTY LAMINATED (10 x 11) 1000D

SizeLaminatedLaminate &

Reinforce 8 bandsMinimum Orders

(meter)Fabric 44” flat

1500 meter

1500 meterFabric 46” flat

1500 meter

1500 meterFabric 68” circular

1500 meter

1500 meterFabric 72” circular

1500 meter

1500 meterFabric 74” circular

1500 meter

1500 meterFabric 80” circular

1500 meter

1500 meter = Available

= Available

= Not Available

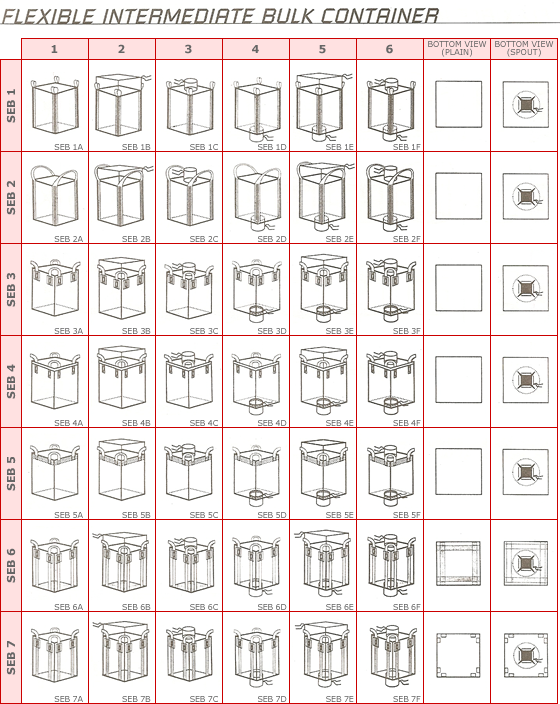

= Not Available - Bag Diagram / Specification

-

Anti Static Bag

Type C bulk bags

Type C bulkbags, also known as conductive bulkbags or ground-able bulkbags, are made from non-conductive polypropylene fabrics interwoven with conducting threads traditionally sewn in a grid pattern. These conducting threads must be electrically interconnected as well as connected to a designated ground/earth during filling and discharging. This connection to the ground/earth during filling and discharging is imperative to the safe use of Type C bulk bags.

- Used safely to transport flammable powders,

- Used safely when flammable solvents or gases are present around the bag,

- DO NOT USE when ground connection is not present or has become damaged.

Type D Bulk Bags

Are also called antistatic Bulks Bags. A type D bag is constructed from antistatic fabric which has antistatic or static dissipative properties to safely prevent the occurrence of incendiary sparks, brush discharges and propagating brush discharges and does not require grounding

Type D bulk bags such as Crohmiq™ bulk bags are manufactured with fabric containing quasi-conductive yarns that safely dissipate static electricity into the atmosphere via safe, low-energy corona discharge. Type D FIBCs can be used to safely package combustible products and handle products in combustible and flammable environments.

- Used safely to transport flammable powders,

- Used safely when flammable solvents or gases are present around the bag,

- DO NOT USE when the surface is contaminated or coated with conductive material such as water or grease.

-

UN Certified Bulk Bags

All Our UN Certified bulk bags, are rigorously tested and examined, are designed specifically for the handling of hazardous materials for Packaging Groups II and III Materials in Chapter 9 of the United Nations "Orange Book".

The "Orange Book" is regulated by a number of international codes based on the United Nations Recommendations on the Transport of dangerous Goods.

Categories of UN Bulk Bags To be able to determine your requirement all we need is the UN classification of the product to be packed and transported. Based on that information we will design your UN Bags to meet your exact requirements.

Height UN-Symbol – Group 1 High (1.2 meter) X Group 2 Medium (1 meter) Y Group 3 Low (0.8 meter) Z -

Container Liner Bag

Liner bags are used for the bulk shipment of dried product formulations. Barrier foil liners offer considerable savings and improved packed product quality.

Common Structures

- Polyester Film - Aluminium Foils - LDPE

Product Features

- Suitable for any Moisture Sensitive Items

- Measurable Pack Performance

- Total Moisture Protection

- Custom made to suit individual requirements